PRECI-DIP has tapped its unique expertise and tested know-how to develop new MIL socket contacts based on the clip technology.

Two socket contact technologies are available:

- hooded contacts using the reversed clip

- hoodless contacts using the Eagle Grip clip.

These contacts have successfully passed all the qualification tests according to AS39029 and are listed on the QPL.

We are also manufacturing the corresponding precision-machined pin contacts.

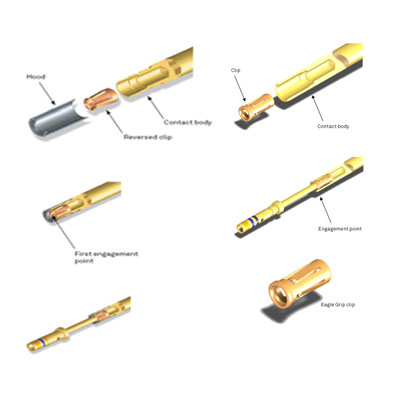

Hooded contacts using the reversed clip patented technology

CONTACT DESIGN

The contact consists of three parts, separately manufactured and made of different base materials. This design allows to optimise the performance and to select the most appropriate production process individually:

- Contact body made of machined brass

- Beryllium-copper clip insert achieved by precision stamping process

- Protection hood made of deep-drawn stainless steel

Separate electroplating processes of body and clip allow the best cost-performance ratio (localized finish). The assembly of the three parts is then carried out on dedicated, fully automatic assembly lines.

Reversed clip contacts are presently available in size 12, 16, 20 and 22. This proprietary technology developed by PRECI-DIP, is protected by international patents.

ADVANTAGES AND CHARACTERISTICS

In comparison with the alternative slotted contact body design, the reversed clip concept has several advantages:

- Smaller difference between insertion and extraction force

- Reduced dispersion of the force values

- Higher redundancy at the level of the contact point, thanks to 6 or 8 contact fingers

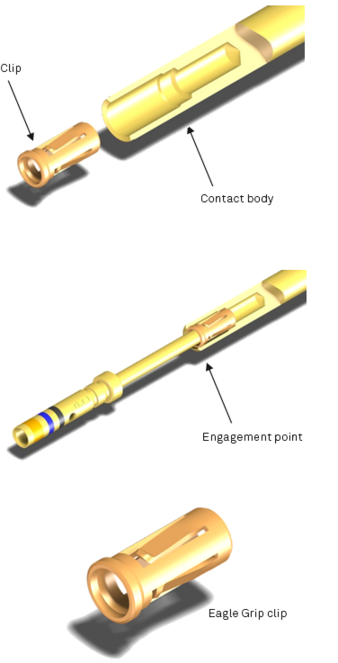

Hoodless contacts using the eagle grip clip patented technology

CONTACT DESIGN

- The hoodless contact consists of two parts: the contact body and the clip (separate pressure member) are made from different base materials.

- The high-speed screw machined contact body is made of brass.

- The use of quality crimping brass renders the annealing operation unnecessary.

- The precision stamped and formed Eagle Grip clip is made of beryllium-copper.

- Separate electroplating processes of the body and clip offer the best cost-performance ratio.

- Automatic assembly lines are designed by our engineers to conduct the body and clip assembly.

- The clip is precisely positioned in the outer shell and firmly held in place between a shoulder and the crimp lip.

- In-line mechanical check is carried out on the assembly machine.

- Eagle Grip clip hoodless contacts are presently available in sizes 16, 20 and 22.

- This PRECI-DIP proprietary technology is protected by international patents.

ADVANTAGES AND CHARACTERISTICS

- 2-piece contact without hood

- Fully automatic assembly process with in-line mechanical check

- Localized finish: body and clip are plated separately

- High surface quality with a stamped and formed clip

- Precision rolling surface finish in the contact area

- Better contact redundancy thanks to 3 or 4 contact fingers

- Repeatability in the manufacturing process of the clip (tooling and stamping)

- Limited difference between insertion and extraction mating forces

- Narrow range of the force values

- Fully integrated manufacturing process on one single production site

- Swiss precision technology

Qualified product list : PRECI-DIP part numbers

SOCKET CONTACTS

|

CONNECTOR TYPE ACC. TO

|

MIL P/N

|

PRECI-DIP P/N

|

MATING SIZE

|

WIRE SIZE

|

CLASS

|

|---|---|---|---|---|---|

|

MIL-DTL-26482, Series 2

AS81703, Series 3 MIL-DTL-83723, Series 1, 3 MIL-DTL-83733 MIL-DTL-12883/40, /41, /47, /48 |

M39029/5-115

M39029/5-116 M39029/5-118 |

83181-7Q4-7110-B1

83191-7Q4-7210-B1 83151-7Q4-7310-B1 |

20

16 12 |

20

16 12 |

B

B B |

|

AS81714, Series II

MIL-C-81511, Series 3, 4 Class L |

M39029/22-191

M39029/22-192 |

83211-7Q4-7010-B1

83231-7Q4-7110-B1 |

22

20 |

22

20 |

B

B |

|

MIL-DTL-26500

MIL-DTL-26518, Class R MIL-C-38300 |

M39029/32-248

|

83171-7Q4-7210-B1

|

16

|

16

|

B

|

|

MIL-DTL-26482, Series 1

|

M39029/32-259

|

83161-7Q4-7110-B1

|

20

|

20

|

A

|

|

MIL-DTL-38999, Series I, III, IV

|

M39029/56-348

M39029/56-351 M39029/56-352 M39029/56-353 |

83011-1P4-7010-B1

83021-1P4-7110-B1 83031-1P4-7210-B1 83041-1P4-7310-B1 |

22

20 16 12 |

22D

20 16 12 |

B

B B B |

|

MIL-DTL-38999, Series II

MIL-DTL-24308 MIL-DTL-55302/68, /71, /75 MIL-DTL-83733 |

M39029/57-354

|

83101-7Q4-7010-B1

|

22

|

22D

|

B

|

|

MIL-DTL-24308

|

M39029/63-368 *

|

83121-7Q4-6110-01

|

20

|

20

|

A

|

|

MIL-DTL-12883/44, /45, /46

|

M39029/101-552

M39029/101-553 |

83431-7Q4-7010-B1

83441-7Q4-7110-B1 |

22

20 |

22

20 |

A

A |

|

*

|

Eagle Grip Clip

|

|---|---|

|

TYPE A

|

Copper alloy

|

|

CLASS A

|

Maximum operating temperature +125°C

|

|

CLASS B

|

Maximum operating temperature +200°C

|

PIN CONTACTS

|

CONNECTOR TYPE ACC. TO

|

MIL P/N

|

PRECI-DIP P/N

|

MATING SIZE

|

WIRE SIZE

|

CLASS

|

|---|---|---|---|---|---|

|

AS81714, Series I

|

M39029/1-100

M39029/1-101 M39029/1-102 M39029/1-103 |

82151-7Q4-01

82161-7Q4-01 82171-7Q4-01 82181-7Q4-01 |

16

16 14 12 |

22

20 16 12 |

B

B B B |

|

MIL-DTL-26482, Series 2

AS81703, Series 3 MIL-DTL-83723, Series 1, 3 MIL-DTL-83733 |

M39029/4-110

M39029/4-111 M39029/4-113 |

82071-7Q4-01

82081-7Q4-01 82091-7Q4-01 |

20

16 12 |

20

16 12 |

B

B B |

|

MIL-DTL-26500

MIL-DTL-26518, Class R MIL-C-38300 |

M39029/31-229

|

82101-7Q4-01

|

16

|

16

|

B

|

|

MIL-DTL-26482, Series 1

|

M39029/31-240

|

82051-7Q4-01

|

20

|

20

|

A

|

|

MIL-DTL-38999, Series I, II, III, IV

MIL-DTL-24308 MIL-DTL-55302/69 MIL-DTL-83733 |

M39029/58-360

M39029/58-363 M39029/58-364 M39029/58-365 |

82011-7Q4-01

82021-7Q4-01 82031-7Q4-01 82041-7Q4-01 |

22

20 16 12 |

22D

20 16 12 |

B

B B B |

|

MIL-DTL-24308

|

M39029/64-369

|

82061-7Q4-01

|

20

|

20

|

A

|

Listed part numbers are of localized finish. For overall plating please contact us.

|

TYPE A

|

Copper alloy

|

|---|---|

|

CLASS A

|

Maximum operating temperature +125°C

|

|

CLASS B

|

Maximum operating temperature +200°C

|